7" /10" /12"

A vinyl record is an analog sound storage medium consisting of a flat disc with an inscribed, modulated spiral groove. Their sound parameters and dimensions are set by international standards. Vinyl records are generally described by the size of their diameter ("12-inch", "10-inch", "7-inch",etc.), the rotational speed at which they are played ("33 1/3" RPM or "45" RPM), and the weight of of the vinyl ("Standard" or "Heavy").

The recording time available on 7" records depends very much on the frequency spectrum, the dynamic range, the width of the stereophonic signal and other characteristics of the recording. While we recommend keeping 7" records playing times to 4.5 - 5.0 minutes at 45 RPM and 6.5 - 7.0 RPM at 33 1/3 RPM, Prime Direct can often accommodate records with playing times of 6.0 - 6.5 minutes at 45 RPM and 8.0 - 8.5 RPM at 33 1/3 RPM.

The 7" format is available on Standard weight (42 ± 7 g) or Heavy weight (70 ± 10 g) vinyl. The 7" Center Hole is available as "Small Hole" or "Big Hole" for Standard weight vinyl and "Small Hole" only for Heavy weight vinyl.

The recording time available on 10" records depends very much on the frequency spectrum, the dynamic range, the width of the stereophonic signal and other characteristics of the recording. While we recommend keeping 10" records playing times to 9.5 - 10.5 minutes at 45 RPM and 13.0 - 14.0 RPM at 33 1/3 RPM, Pirates Press can often accommodate records with playing times of 10.5 - 11.5 minutes at 45 RPM and 14.0 - 15.5 RPM at 33 1/3 RPM.

The recording time available on 12" records depends very much on the frequency spectrum, the dynamic range, the width of the stereophonic signal and other characteristics of the recording. While we recommend keeping 12" records playing times to 13.5 - 14.5 minutes at 45 RPM and 19.0 - 20.0 RPM at 33 1/3 RPM, Pirates Press can often accommodate records with playing times of 14.0 - 15.5 minutes at 45 RPM and 20.0 - 22.5 RPM at 33 1/3 RPM.

The 12" format is available on Standard weight (140 ± 10 g) or Heavy weight (180 ± 10 - 220 ± 10 g) vinyl. The 12" Center Hole is available as "Small Hole" only.

7"

Traditionally, the 7" 45 RPM format has been used for "Singles" and would contain one item per side, but they are also great for "Extended Play" (EP) releases, multi-track records that play longer than the single-item-per-side records. Since the 7" can be cut at either 45 RPM or 33 1/3 RPM, longer recording times can be achieved at the expense of attenuating and compressing the sound to reduce the width required by the groove.The recording time available on 7" records depends very much on the frequency spectrum, the dynamic range, the width of the stereophonic signal and other characteristics of the recording. While we recommend keeping 7" records playing times to 4.5 - 5.0 minutes at 45 RPM and 6.5 - 7.0 RPM at 33 1/3 RPM, Prime Direct can often accommodate records with playing times of 6.0 - 6.5 minutes at 45 RPM and 8.0 - 8.5 RPM at 33 1/3 RPM.

The 7" format is available on Standard weight (42 ± 7 g) or Heavy weight (70 ± 10 g) vinyl. The 7" Center Hole is available as "Small Hole" or "Big Hole" for Standard weight vinyl and "Small Hole" only for Heavy weight vinyl.

10"

Before the early 1950s the 33 1/3 RPM LP was most commonly found in a 10" format. The 10" format disappeared from United States stores around 1950, but remained common in some markets until the mid-1960s. The 10" vinyl format was resurrected in the 1970s for marketing some popular recordings as collectible.The recording time available on 10" records depends very much on the frequency spectrum, the dynamic range, the width of the stereophonic signal and other characteristics of the recording. While we recommend keeping 10" records playing times to 9.5 - 10.5 minutes at 45 RPM and 13.0 - 14.0 RPM at 33 1/3 RPM, Pirates Press can often accommodate records with playing times of 10.5 - 11.5 minutes at 45 RPM and 14.0 - 15.5 RPM at 33 1/3 RPM.

12"

The 12" vinyl format is often referred to as an LP ("Long Play") as it can play much longer than the "Single" or "Extended Play" 7". LPs were 10" records at first, but soon the 12" size became by far the most common. While the 12" format is most commonly used for LP purposes, it is also quite common to see Singles and EPs pressed on 12" vinyl.The recording time available on 12" records depends very much on the frequency spectrum, the dynamic range, the width of the stereophonic signal and other characteristics of the recording. While we recommend keeping 12" records playing times to 13.5 - 14.5 minutes at 45 RPM and 19.0 - 20.0 RPM at 33 1/3 RPM, Pirates Press can often accommodate records with playing times of 14.0 - 15.5 minutes at 45 RPM and 20.0 - 22.5 RPM at 33 1/3 RPM.

The 12" format is available on Standard weight (140 ± 10 g) or Heavy weight (180 ± 10 - 220 ± 10 g) vinyl. The 12" Center Hole is available as "Small Hole" only.

insurance

Test pressings are something that we strongly recommend, but do not require. While they may add a week or two to turnaround time, they are a cheap insurance policy! They allow you to check the overall quality of the (music) cut that we have made before we produce your order. In general, we send you 5 test pressings that you need to approve. Once approved, we can then proceed with the rest of the production - and you can rest assured that the final product will sound as good, or better than the tests! If for any reason you are not happy with the test pressings, we have the ability to help find out what went wrong and fix it before it becomes a major issue.

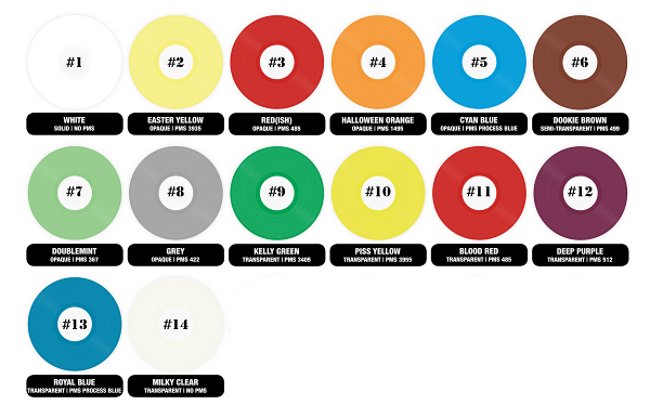

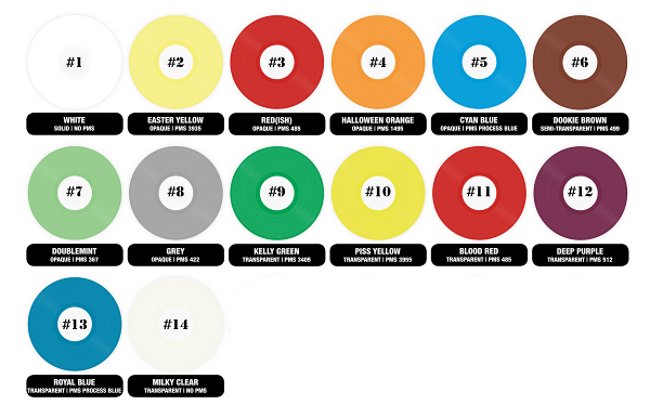

Transparent and opaque coloured vinyl

we are able to offer a large selection of coloured vinyl in opaque and transparent colors in one and multi colour.

Single coloured records are manufactured From 14 standard colours (as below) of which there are 6

transparent colours and 8 solid colours. These are all colours that are standard.

We are also capable of making special colours in accordance with a Pantone colour reference. We cannot guarantee an exact colour match but we create a colour that is

as close as possible to your chosen colour. It is not possible to make a claim due to the fact

that the colour doesn’t match exactly, this is a non standard process where we do all that we

can to make the colour as close as possible. Some colours are only possible to make in either

transparent or solid versions, please ask for advice when choosing a colour.

Multi Colour Speckles and more

We are able to offer a fabulous range of real eye catching designs.

1.) COLOURED RECORDS WITH SPECKLES – the base colour can be either solid or transparent, however the speckles must be chosen from one of the milky colours from the standard range of colours

2.) TWO COLOURED RECORDS – half/half – Can be made from a combination of both transparent and milky colours

3.) TWO COLOURED RECORDS – COLOUR IN COLOUR – when we press the record in this fashion we get a random effect of a colour within a colour.

4.) TWO COLOURED RECORDS – SIDE A/SIDE B – this type of record is ALWAYS made from solid colours. The effect is totally random on both sides of the record.

5.)THREE COLOURED RECORDS – approximately 120° segments – this type of record can be made of a combination of both solid and transparent colours. The maximum amount of records that can be manufactured using this effect is 300 units

Below is a small selection

1.) COLOURED RECORDS WITH SPECKLES – the base colour can be either solid or transparent, however the speckles must be chosen from one of the milky colours from the standard range of colours

2.) TWO COLOURED RECORDS – half/half – Can be made from a combination of both transparent and milky colours

3.) TWO COLOURED RECORDS – COLOUR IN COLOUR – when we press the record in this fashion we get a random effect of a colour within a colour.

4.) TWO COLOURED RECORDS – SIDE A/SIDE B – this type of record is ALWAYS made from solid colours. The effect is totally random on both sides of the record.

5.)THREE COLOURED RECORDS – approximately 120° segments – this type of record can be made of a combination of both solid and transparent colours. The maximum amount of records that can be manufactured using this effect is 300 units

Below is a small selection

extensive choice

The extensive array of packaging we supply to our customers is perhaps their greatest strength and advantage in this re-emerging market for vinyl. What we have been able to accomplish to make our records unique from the others on a record store rack is truly what sets us apart from other manufacturers. Browsing our gallery, or taking a dive into our Record of The Week Blog are both fantastic ways for you to help us prove our point! Virtually all of our printwork is made alongside the vinyl in Europe, at the same facility, under the same roof. This gives us the benefit of an unbelievably unique streamlined printing process with some of the most advanced technology, quickest turnaround times, and competitive pricing anywhere in the business.

Common Finishes

Semi-Gloss Machine Varnish - If you do not specify, this is the finish that will likely be used on your product. It is applied as a liquid, on top of the printing, aiding in drying, and protecting the ink from smearing.

High Gloss Machine Varnish - This high gloss finish is applied as a liquid, on top of the printing. It is great for photos and lots of other design types.

Matte Machine Varnish - This matte finish is applied as a liquid, on top of the printing, giving the product a slightly silky feel instead of a semi-gloss or gloss. a popular choice for innersleeves and booklets.

UV Gloss Laminate - This is the glossiest gloss finish we offer, as a roll of gloss laminate is applied on top of the printing, adding additional structure to the product as well as a stellar look.

Matte Laminate - This is the most expensive and arguably nicest finish we offer. A matte laminate is applied on top of the printing, adding a silky feel and additional structure to the product. Perfect for a high end gatefold jacket!

Reverseboard Printing - When used in combination with one of our stocks having an uncoated reverse-side, we can print on that uncoated side, giving the final product a rougher, uncoated look. This is perfect for designs based on paintings, in addition to many other brilliant applications. One of our least expensive finishes, reverseboard printing can really turn a piece of printwork from something that looks mass produced into a work of art. It is important to note that because the stock is uncoated, it has a tendency to soak up more ink, and even though we compensate for that, can result in a washed out look, depending on your design.

Spot UV (or Matte) Varnish - We are able to apply a liquid gloss or matte varnish only in a particular (custom) area of your design, highlighting just that part in the desired finish. This is most commonly used in combination with another finish to increase the contrast in finishes - for example, Spot UV Gloss on Matte Laminate. Please note, Spot Gloss/Matte often does not appear well on things made with reverseboard printing, as the uncoated nature of the stock absorbs more of the applied varnish than usual.

High quality face printing

The face printing on our CDs and DVDs is as high quality as you'll find anywhere. Depending on your design, we can utilize both silkscreening or offset printing technology - we even include FULL COLOR face printing FOR FREE on all of our CD packages! The bottom line is that we want your CD's to look as nice as possible and we'll do everything in our power to make sure of it!!

Stamp, emboss, deboss & die cut

Foil Stamping - This is the application of pigment or metallic foil to paper. A heated die is stamped onto the foil, making it adhere to the surface leaving the design of the die on the paper. We have a wide range of colors available. CLICK HERE to view our Foil Chart.

Embossing - Typically accomplished by applying heat and pressure with male and female dies, usually made of copper or brass, that fit together and squeeze the fibers of the substrate. The combination of pressure and heat raises the level of the image higher than the substrate.

Debossing - This is similar to embossing, but recesses the design rather than raising it.

Custom Die-Cut - A die is a specialized tool used in manufacturing industries to cut or shape material using a press. Done after printing as part of the finishing process, diecuts are areas of the document that are partially or completely cut, shaped, or cut-out in a variety of shapes. We can use customized dies to create a truely unique package for your product.

Embossing - Typically accomplished by applying heat and pressure with male and female dies, usually made of copper or brass, that fit together and squeeze the fibers of the substrate. The combination of pressure and heat raises the level of the image higher than the substrate.

Debossing - This is similar to embossing, but recesses the design rather than raising it.

Custom Die-Cut - A die is a specialized tool used in manufacturing industries to cut or shape material using a press. Done after printing as part of the finishing process, diecuts are areas of the document that are partially or completely cut, shaped, or cut-out in a variety of shapes. We can use customized dies to create a truely unique package for your product.

Wrapped to thrill

A CD or DVD can be a fantastic addition to any vinyl project, and they clearly still have the ability to be sold as a standalone product as well. For our customers, their use is quite varied, probably close to 50/50. The options we have to package CDs and DVDs are as diverse as any company out there. Almost all of our CD and DVD packaging is also made in Europe alongside our vinyl packaging, thus making it very easy to coordinate it with a vinyl project, or even just a European tour. We have literally hundreds of different (standard) products to choose from, and we're constantly creating new ones! Our most common products are a variety of cardboard sleeves, digipaks, digifiles (digipaks without the plastic tray), and even super deluxe casewrapped boxsets... and yes, of course the traditional DVD Amaray case, and jewel case for CD's, - and even it's newer slicker cousin the "super" jewel case.

If you don't see a template for the product you're looking for to house your next CD or DVD on our site, just ask, because we've probably made it before - and if not, we certainly can! With one of the largest and best full service printing facilities in the world essentially under the same roof as our CD and DVD lines, we have a world of packaging at your fingertips - and even making a custom product does NOT have to take an eternity and involve a series of hoops for you to jump through. We can make it all very easy for you, so you can spend your time selling your product, not making it - leave that to us, that's our job!

If you don't see a template for the product you're looking for to house your next CD or DVD on our site, just ask, because we've probably made it before - and if not, we certainly can! With one of the largest and best full service printing facilities in the world essentially under the same roof as our CD and DVD lines, we have a world of packaging at your fingertips - and even making a custom product does NOT have to take an eternity and involve a series of hoops for you to jump through. We can make it all very easy for you, so you can spend your time selling your product, not making it - leave that to us, that's our job!